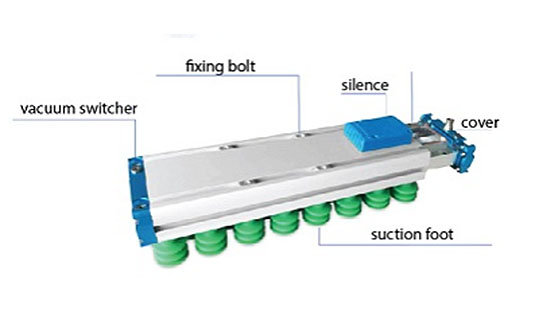

Ụkwụ na-aṅụ

Iko mmiri bụ ihe njikọ n'etiti workpiece na agụụ usoro. Njirimara nke iko mmiri ara ahọpụtara nwere mmetụta bụ isi na ọrụ nke sistemu oghere niile.

Ụkpụrụ bụ isi nke agụụ sucker

1. Olee otú na workpiece adsorbed na mmiri iko?

E jiri ya tụnyere gburugburu ebe ikuku na-ekpo ọkụ, enwere mpaghara nrụgide dị ala (vacuum) n'etiti iko mmiri na ihe na-arụ ọrụ.

N'ihi nrụgide nrụgide dị iche, a na-agbanye workpiece na iko mmiri ara.

Δ p = p1-p2.

Ike ahụ dabara na ọdịiche nrụgide na mpaghara dị irè, F~ Δ pandF ~ A à F = Δ px A.

2. Akụkụ dị mkpa nke iko agụụ

Olu dị n'ime: olu dị n'ime nke iko mmiri ara nke a na-ewepụ na-emetụta ozugbo oge mgbapụta.

Obere radius curvature: obere radius nke workpiece nke iko mmiri nwere ike ijide.

Ọrịa strok nke egbugbere ọnụ akara: na-ezo aka n'ebe dị anya abịakọrọ ka emechara iko mmiri ahụ. Ọ na-emetụta ozugbo mmegharị nke egbugbere ọnụ akara akara.

Ọrịa strok nke iko mmiri: mmetụta na-ebuli elu mgbe a na-agbanye iko mmiri ara.

Nhazi nke iko mmiri

Iko mmiri a na-ejikarị agụnye iko mmiri ara ehi ewepụghị, iko mmiri ara ara, iko mmiri ara elliptical na iko mmiri pụrụ iche.

1. Iko mmiri na-ekpo ọkụ dị larịị: nhazi ọkwa dị elu; Obere imewe na obere olu dị n'ime nwere ike ibelata oge njide; Nweta ike n'akụkụ dị elu; N'elu larịị nke workpiece, obosara akara egbugbere ọnụ nwere ezigbo akara njirimara; Ọ nwere ezigbo nkwụsi ike mgbe ị na-ejide workpiece; Ọdịdị agbakwunyere nke nnukwu iko mmiri mmiri nwere ike nweta ike mmịpụta dị elu (dịka ọmụmaatụ, iko ụdị ụdị diski); Nkwado n'okpuru; Nnukwu ma dị irè iko mmiri dayameta; Enwere ọtụtụ ụdị ihe iko mmiri ara. Ebe ngwa a na-ahụkarị nke iko mmiri mmiri na-agbanwe ugboro ugboro: ijikwa ihe arụrụ arụ dị larịị ma ọ bụ ubé nwere elu dị larịị ma ọ bụ nke siri ike, dị ka efere ọla, katọn, efere iko, akụkụ plastik na efere osisi.

2. Njirimara nke iko mmiri ara ehi corrugated: 1.5 fold, 2.5 fold and 3.5 fold corrugated; Ezigbo mgbanwe na elu na-enweghị isi; Enwere mmetụta na-ebuli elu mgbe ị na-ejide workpiece; Nkwụghachi ụgwọ maka ịdị elu dị iche iche; Jidesie ike na-adịghị ike workpiece; Ngwongwo ala dị nro; Aka na mgbago elu nke iko mmiri ara nwere ike siri ike; egbugbere ọnụ akara akara conical dị nro ma na-agbanwe agbanwe; Nkwado n'okpuru; Enwere ọtụtụ ụdị ihe iko mmiri ara. A na-ahụkarị ubi ngwa nke iko mmiri ara ehi: ijikwa ụdị efere na arụghị arụ ọrụ, dị ka efere igwe ụgbọ ala, katọn, akụkụ rọba, ngwaahịa nkwakọ ngwaahịa aluminom/thermoplastic, na akụkụ eletrọnịkị.

3. Oval mmiri ara ehi: na-eji nke ọma ihe n'elu absorbable; Kwesịrị ekwesị maka ogologo convex workpiece; Vacuum sucker nwere ike emelitere; Obere nha, nnukwu mmiri ara; Nke a na-ahụkarị dị ka iko mmiri ara ehi dị larịị na corrugated; Ihe dị iche iche nke iko mmiri; Ihe agbakwunyere agbakwunyere nwere ike ijide nnukwu (iko ụdị diski). Mpaghara ngwa a na-ahụkarị nke iko mmiri oval: ijikwa ihe dị warara na obere workpieces: dị ka akwa ọkpọkọ, ihe eji arụ ọrụ geometric, ibe osisi, okpokolo agba windo, katọn, ngwaahịa nkwakọ ngwaahịa tin foil/thermoplastic.

4. Iko mmiri pụrụ iche: ha dị ka iko mmiri nkịtị; Ihe dị iche iche nke ihe iko iko na udi na-eme ka ọ dabara na mpaghara / ụlọ ọrụ ngwa ngwa; Ụdị ngwa mpaghara nke iko mmiri mmiri pụrụ iche: ijikwa workpieces nwere arụmọrụ pụrụ iche. Dị ka usoro elu na-esighị ike, nke nwere oghere na nrụrụ.

Oge nzipu: Eprel-07-2023